Home / All

casting part

60 results

ViewShowcase

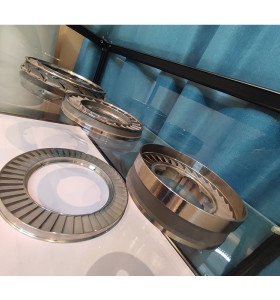

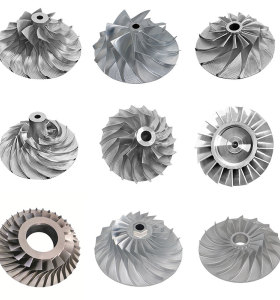

Custom Turbine Compressor Rotor Blades Nickel Alloy Titanium Inconel 600 625 Casting OEM ODM Support

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Water Soluble Wax Type Wax Iniection Machine

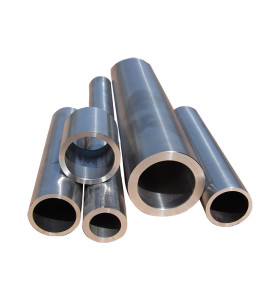

C -type Cylinder of Wax Injection Machine

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy Aluminum alloy gas turbine aviation and nuclear power plant casting factory

Nickel-based alloy titanium alloy gas turbine aviation and nuclear power plant casting factory

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

- Introduction to high temperature alloysNov 10,2023

- About CNC machiningNov 9,2023

O.B.T Manufacture

O.B.T Manufacture