casting part Categories

Foundry Material

Colloidal silica

Mullite sand

Fused Silica Products

Fused Silica Products

Natural high purity quartz its microstructure at high temperature becomes the amorphous structure of the fused silica.

Is molten particles and silicon powder with high quality fused silica, through special crushing grinding process, the product high purity, controllable particle size distribution.

The main characteristics of fused silica are:

●High temperature resistance, good whiteness, melting point 1750 ℃.

●Excellent low electrical insulation.

●High hardness, high resistance to wear.

●Low expansion coefficient is low.

●Chemical properties of stability, in addition to react with hydrogen fluoride ether and alkali, does not react with any other material.

Areas of application:

Photovoltaic materials, electronic materials, refractory materials, investment casting, high voltage electrical insulation materials, paint coating, silicone rubber, special ceramics, advanced materials, fine chemical industry, aerospace and other industries.

Casting Wax

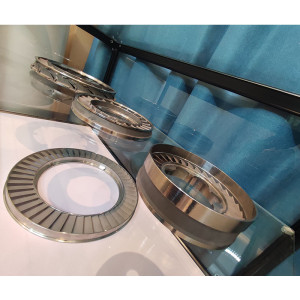

Gas Turbine Wheel Parts

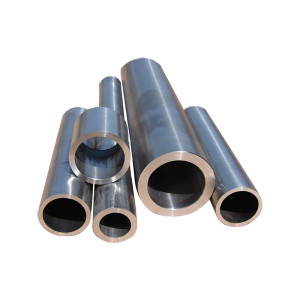

Stainless Steel and Copper Products

Casting Machine

CNC Machining

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

- Introduction to high temperature alloysNov 10,2023

- About CNC machiningNov 9,2023

O.B.T Manufacture

O.B.T Manufacture