THE GUARANTEE OF QUALITY COME FROM STANDARD SERVICES

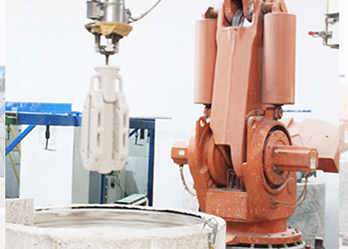

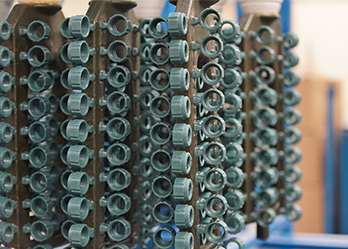

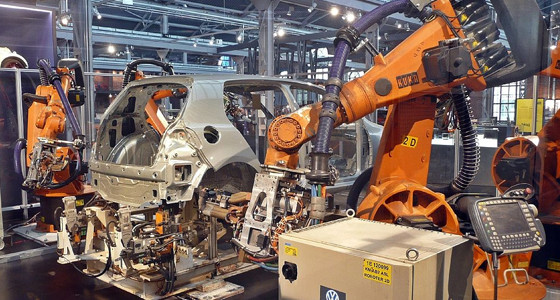

- ABOUT USOBT Mining as the China No.1 biggest manufacturer for mullite sand which has been supplying to Germany Thyssenkrupp,totally capacity 200000tons and OBT casting subsidiary factory specializing in R&D and manufacturing of precision casting equipment, precision metal products processing and precision casting process. Comprehensive company for technical research and supply for the invesment casting sand and machines.With more than 16 years of development, At present,OBT casting factory has produced more than 70 kinds of precision casting equipment. It is the most advanced silica sol shell casting process equipment, which provides manufacturing guarantee for the production of excellent product parts.Relying on Tsinghua University and the University of Petroleum, the company now has a group of capable management personnel and a high-quality professional technical team with strong technical development strength. In the tenet of

-

16 Years of Experience Technical Team

16 Years of Experience Technical Team -

Stable and perfect supply chain management system

Stable and perfect supply chain management system -

On-time delivery rate >98%

On-time delivery rate >98% -

Quality product production guarantee

Quality product production guarantee -

High Standard Inspection Process

High Standard Inspection Process -

Reliable quality assurance

Reliable quality assurance

-

SERVICE

OBT can give you good service .We believe every customer are all worthy to be treated wholeheartedly As we are a grateful and responsible factory for more than 16 years old.

Free Sample

Free Sample Custom Made

Custom Made One Stop Solution

One Stop Solution

-

- 400Cooperative Enterprise

- 200+Client

- 99%Satisfaction

-

NEWS

OBT is committed to providing investment casting materials and equipments for 16 years. We can also provide more service according to customer's design requirement.

-

Precision casting mullite sand2019-04-05Our head of the Vietnamese market visits customers 5-10 times a year, communicates and guides customers on site, Customers are very satisfied with our products, and we are promoting some exciting new customized production projects!

Precision casting mullite sand2019-04-05Our head of the Vietnamese market visits customers 5-10 times a year, communicates and guides customers on site, Customers are very satisfied with our products, and we are promoting some exciting new customized production projects! -

Visiting Vietnamese customers2019-04-05Our head of the Vietnamese market visits customers 5-10 times a year, communicates and guides customers on site, Customers are very satisfied with our products, and we are promoting some exciting new customized production projects!

Visiting Vietnamese customers2019-04-05Our head of the Vietnamese market visits customers 5-10 times a year, communicates and guides customers on site, Customers are very satisfied with our products, and we are promoting some exciting new customized production projects! -

Silica sol performance characteristics2018-06-06Colloidal silica can be used as a binder commonly used in coatings. What characteristics should colloidal silica have in application? Colloidal silica, also known as silicic acid sol, is a high-temperature hydrophilic and special binder. It is a concentrated form of water glass after ion exchange. The molecular formula is mSi02·nH2O, which is the binding ability of silica gel with milky white or light cyan solution. More powerful than water glass and ethyl silicate, used in water-based coatings. Colloidal silica is a water based binder. Commonly used water glass is ion exchanged to remove sodium ions, chloride ions and other impurities, and then it is often pressed or concentrated in a vacuum. In the investment casting, the sodium-based colloidal silica has a colloidal particle diameter of 8 to 12 μm. colloidal silica is currently widely used in the production of directional solidification, single crystal casting and high temperature alloy casting for surface grain refinement.

Silica sol performance characteristics2018-06-06Colloidal silica can be used as a binder commonly used in coatings. What characteristics should colloidal silica have in application? Colloidal silica, also known as silicic acid sol, is a high-temperature hydrophilic and special binder. It is a concentrated form of water glass after ion exchange. The molecular formula is mSi02·nH2O, which is the binding ability of silica gel with milky white or light cyan solution. More powerful than water glass and ethyl silicate, used in water-based coatings. Colloidal silica is a water based binder. Commonly used water glass is ion exchanged to remove sodium ions, chloride ions and other impurities, and then it is often pressed or concentrated in a vacuum. In the investment casting, the sodium-based colloidal silica has a colloidal particle diameter of 8 to 12 μm. colloidal silica is currently widely used in the production of directional solidification, single crystal casting and high temperature alloy casting for surface grain refinement.

Requst a quote

Contact OBT Views Our beloved Clients

Please send your message to us

- Name

- Tel

- *Title

- *Content

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

- Introduction to high temperature alloysNov 10,2023

- About CNC machiningNov 9,2023

O.B.T Manufacture

O.B.T Manufacture