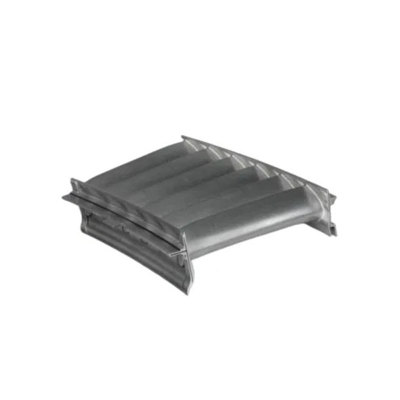

Home / All / Gas Turbine Wheel Parts / Custom NGV Nozzle Guide Vanes Nickel Alloy Titanium Inconel 600 625 Casting OEM ODM Support

Custom NGV Nozzle Guide Vanes Nickel Alloy Titanium Inconel 600 625 Casting OEM ODM Support

Detail Information

NGV, which stands for Nozzle Guide Vanes, is an important component in gas turbines and turbines. The main function of these blades is to guide the flow of gas flowing through the blades at high speed so that the gas can enter the rotating blade area in the most efficient manner. The following is a detailed introduction to NGV:

Gas Guidance: The NGV is located at the inlet of the turbine, close to the rotating blade area. When high-speed gas flow enters the turbine, the NGV guides the gas into the rotating blades through its special blade shape and positioning to obtain optimal kinetic energy conversion.

Blade design: The blade design of NGV is key, usually using aerodynamic principles to ensure the optimal speed and direction of gas flow. These blades are usually the product of aerodynamic design, intended to reduce gas flow losses and increase the efficiency of the gas turbine.

Thermal resistance: NGVs are often exposed to high temperature and high pressure gas flows, so they must be able to withstand high temperature and high pressure environments. This means they are typically made from high-temperature alloys to ensure long-term performance and longevity.

Adjustable: In some modern gas turbines, the NGV is adjustable. This allows the operator to change the angle of the blades as needed to optimize the direction of the gas flow, thereby improving the performance of the machine.

Reduced vibration: NGVs also help reduce vibration within the turbine, which is critical to the reliability and longevity of the machinery.

In summary, NGVs play a key role in gas turbines and turbines, and their design and performance directly affect the efficiency and performance of the machinery. These blades are the product of advanced engineering, carefully designed and optimized to ensure optimal kinetic energy conversion and mechanical performance.

Related Products

Please send your message to us

- Name

- Phone

- *Title

- *Content

- KEEP UP TO DATE

- Sign up for our newsletter and follow us on social media

subscription

NAVIGATION

LATEST POSTS

- Introduction to high temperature alloysNov 10,2023

- About CNC machiningNov 9,2023

O.B.T Manufacture

O.B.T Manufacture